In the expansive realm of industrial production and environmental protection, filtration technology assumes a pivotal role. Among various filtration media, polypropylene monofilament and multifilament filter cloths stand out as essential materials, widely utilized across diverse industries due to their distinctive performance advantages. These filter cloths have become indispensable tools for enhancing production efficiency, ensuring product quality, and fostering sustainable manufacturing practices.

Polypropylene Monofilament Filter Cloth

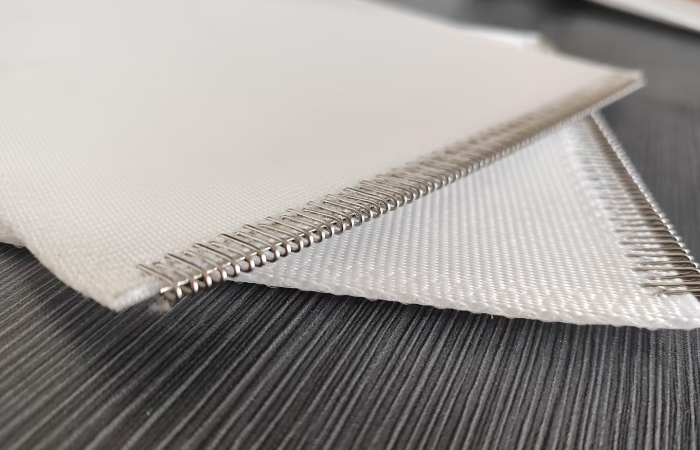

Polypropylene (PP) monofilament filter cloth features a single-fiber structure, wherein each fiber is independently. This design minimizes fiber intersections and reduces surface roughness, thereby significantly enhancing both filtration efficiency and ease of cleaning.

Multifilament Filter Cloth

Multifilament filter cloth exhibits higher strength and superior elasticity by twisting multiple fine fibers together to withstand greater mechanical stress. Its generally rougher surface facilitates the formation of a stable filter cake layer while improving filtration accuracy.

Applications of Polypropylene Monofilament Filter Cloth

a.Sewage Treatment: Polypropylene monofilament filter cloth is favored in municipal sewage treatment and industrial wastewater management due to its excellent chemical stability. It is primarily employed for sludge dewatering and the removal of suspended solids.

b. Chemical Filtration: In chemical manufacturing processes, polypropylene monofilament filter cloth is extensively used for filtering and purifying chemical raw materials as well as recovering catalysts owing to its remarkable resistance to acids and alkalis along with anti-aging properties.

c. Pharmaceutical Industry: Pharmaceutical production has extremely strict hygiene standards. polypropylene monofilament filter cloth-being non-toxic, odorless, and easy to clean-is utilized for filtering and purifying pharmaceutical raw materials as well as maintaining cleanliness in pharmaceutical production lines.

Applications of Multifilament Filter Cloth

a. Mining Filtration:In the fields of mining and mineral processing, effective separation of a substantial quantity of solid particles is essential. Multifilament filter cloth, characterized by its high strength and excellent breathability, exhibits outstanding performance in slurry filtration and concentrate dewatering.

b. Food Processing: Although polypropylene materials have limitations in food-grade applications, multifilament filter cloth with specific formulations can be used for preliminary filtration and clarification of food raw materials, ensuring food safety and quality.

c. Textile Dyeing: In the textile dyeing industry, multifilament filter cloth is commonly used for the filtration of dyes and additives, as well as the removal of suspended solids in wastewater treatment. Its textured surface promotes uniform formation of filter cakes, enhancing overall filtration efficiency.

Bolian polypropylene monofilament filter cloth is mainly used in HVBF, while multifilament filter cloth is primarily used in tower press filter. Both are woven using a fully imported production line, ensuring that each piece of filter cloth meets ISO9001 .