PP filter cloth, also known as polypropylene filter cloth, is a filtration material made from polypropylene as the primary raw material. PP filter cloth is widely used in the liquid-solid separation field due to its unique properties.

Polypropylene (PP) is a high molecular weight polymer known for its exceptional chemical stability, which allows it to maintain integrity across a broad spectrum of chemical environments. The pH range for PP filter cloth is between 1 and 13, meaning that, except for a few highly corrosive substances like concentrated nitric acid and Sodium hydroxide, PP filter cloth offers excellent resistance to most chlorinated solvents and aromatic compounds.

PP filter cloth also has excellent physical properties. It has a low density, approximately 0.905 g/cm³, which reduces the burden on filtration equipment during operation and helps extend the lifespan of the equipment. Furthermore, it has good electrical conductivity, which effectively prevents static accumulation, ensuring safety during the filtration process. Additionally, the tensile strength of PP filter cloth approaches that of nylon, enabling it to uphold structural integrity under substantial filtration loads.

Durability is another significant advantage of PP filter cloth. Its abrasion resistance and corrosion resistance enable it to maintain long-term stability in harsh working environments. Under normal operating conditions, the working temperature of PP filter cloth does not exceed 90°C.

PP filter cloth also offers good environmental benefits. Polypropylene is a recyclable and eco-friendly material, and the used PP filter cloth can be recycled and reused, reducing environmental pollution.

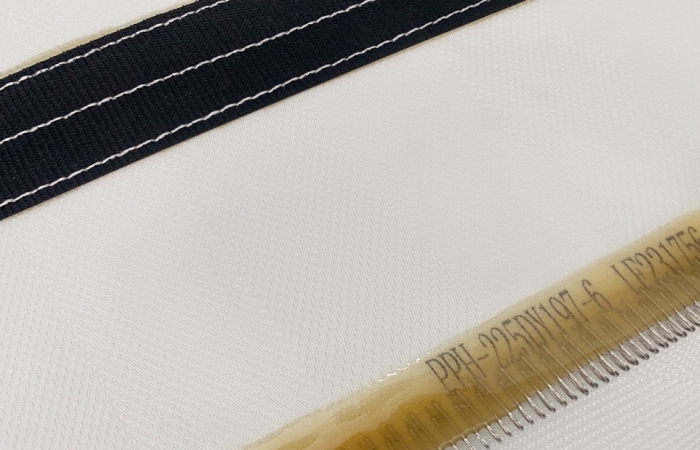

Bolian offers a wide range of PP filter cloth products, including horizontal belt filter cloths, Tower filter press cloths, and press filter cloths. These fabrics are characterized by high strength coupled with low elongation and high density; they find widespread application across various industries such as food processing, chemicals manufacturing, mining and environmental protection for liquid-solid separation.