Rubber filter cloth and filter press cloth play important roles in the filtration industry. While their functions are similar, there are differences in material, structure, performance, and application.

Material and Structure:

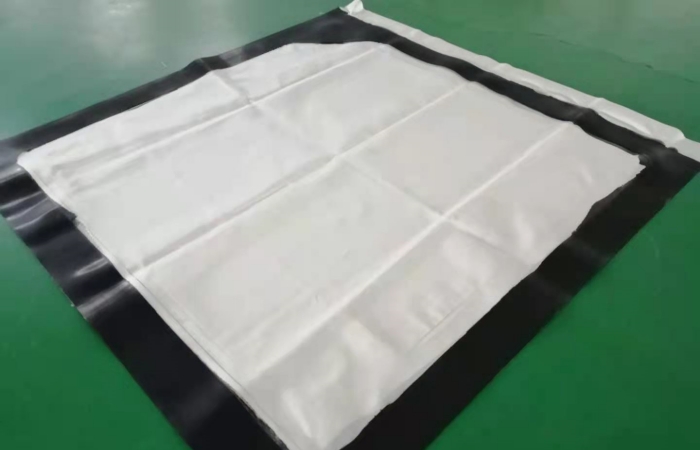

Rubber-coated Filter Cloth: it is a composite material made by attaching a rubber layer to the surface of the filter cloth through a specific process. In comparison, filter press cloth is a flat filtration material woven from interweaving multiple layers of fibers or yarns. Its material is relatively simple and mainly relies on the physical properties and chemical stability of the fibers or yarns to achieve filtration.

Performance Characteristics:

Filtration Performance: The rubber layer on the surface of the rubber-coated filter cloth effectively prevents the penetration and filtrate leakage, facilitating the formation and release of filter cakes. In contrast, the multi-layer fiber structure of filter press cloth forms a relatively dense filtration layer, which has a strong ability to retain fine particles.

Durability: The durability of rubber-coated filter cloth is mainly attributed to the protection provided by the rubber layer, which effectively resists abrasion, corrosion, and stretching. In comparison, filter press cloth is more susceptible to damage from material impact, friction, and corrosion.

Cleaning and Maintenance: Due to the presence of the rubber layer, rubber-coated filter cloth is difficult to damage during cleaning and easily to recover original filtration performance. While filter press cloth, due to its multiple fiber structure, requires extra care during cleaning to avoid damage.

Application industry:

Rubber-coated filter cloth is mainly suitable for applications that require high filtration precision, high durability, and easy cleaning and maintenance, such as solid-liquid separation processes in the chemical, pharmaceutical, and food industries. While filter press cloth is more suitable for applications where filtration precision is not as critical, but there are higher demands for filtration area and speed. It is commonly used in industries like environmental protection, metallurgy, and mining for wastewater treatment and solid waste recovery.