The belt filter cloth joint treatment process is a crucial step in the production of filter cloth, especially in filtration applications. The joint treatment not only affects the filtration efficiency but also directly impacts the stable operation and lifespan of the equipment.

Basic Steps of Belt Filter Cloth Joint Treatment

Preparation Before performing the joint treatment, it is essential to prepare the required materials and tools, including but not limited to: stainless steel clipper, sealing glue, stainless steel wire, protective cloth (if needed), etc. Additionally, ensure that the work area is clean and tidy to prevent dust and debris from affecting the quality of the joint.

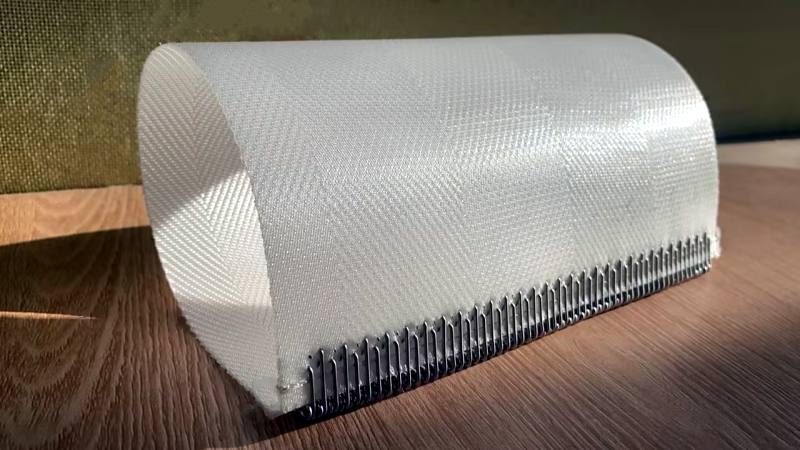

Clipper Installation During the clipper installation process, ensure that the clipper teeth are continuous and the pins pass through smoothly. The steel connection should be straight and flat, ensuring the filter cloth operates properly once it is put into the machine.

Glue Coating After the clipper is installed at both ends of the filter cloth, ensure the clipper fits tightly with the cloth. Then, evenly apply the sealing glue to the clipper. The amount of glue used should be moderate. The purpose of applying the glue is to protect the fibers or the protective cloth. During this process, ensure that the glue fully penetrates the fabric and is firmly secured.

Protective Cloth Installation and Adjustment If a protective cloth is included with the filter cloth, it should be laid flat at the joint and secured using Velcro or stitching to protect the joint from material abrasion and external environmental factors.

Bolian filter cloths undergo strict quality control at every step, following ISO 9001 standards to ensure that every filter cloth meets the quality requirements. The joint steel clipper is available in both steel wire clipper and steel plate clipper options.