Filter fabrics, serving as a crucial filtering medium, find extensive applications across various industrial sectors, including metallurgy, chemicals, pharmaceuticals, and food processing. The weaving method of filter fabric is a pivotal factor determining its performance. This article will discuss several primary weaving techniques of filter fabrics, namely plain weave, twill weave, satin weave, double - layer weave, and multi - layer composite.

Plain Weave

Plain weave, as a traditional and basic weaving method, interlaces the warp and weft yarns at regular intervals, forming a stable structure. This weaving method results in a flat fabric structure with uniform pore sizes, providing good performance in collecting fine particles. Fabrics woven in a plain weave exhibit a compact structure and high precision. However, due to the tight interlacing of warp and weft yarns, their air permeability is relatively poor.

Twill Weave

Twill weave, on the other hand, interlaces the warp and weft yarns at staggered positions, creating continuous diagonal lines on the fabric. This weaving method significantly enhances the strength and wear resistance of the fabric. Compared to plain weave, twill weave fabrics have more sparse interlacing points, offering better air permeability while maintaining good filtration performance.

Satin Weave

Satin weave is a special weaving method where the warp and weft yarns interlace over a longer distance, forming a smooth surface on the fabric. This method leads to a fabric with larger pores, enabling better air permeability and a higher filtration speed.

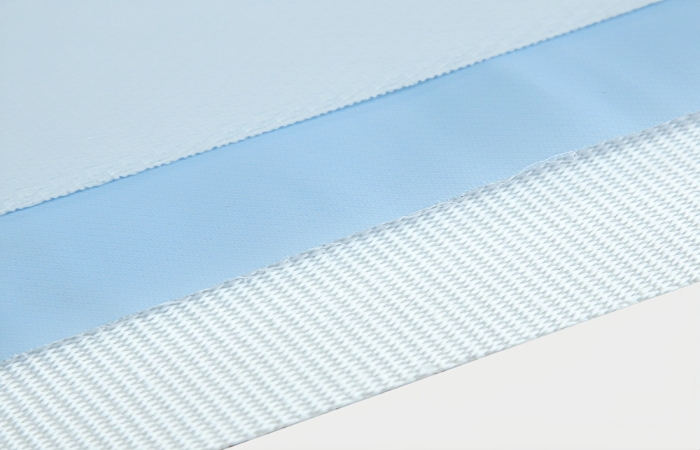

Double-Layer Weave and Multi-Layer Composite

Apart from the three basic weaving techniques mentioned above, filter fabrics can also be crafted using double - layer and multi - layer composite techniques to meet the diverse performance demands of different industries.

Bolian Filtration Materials strictly adheres to the manufacturing process and conducts comprehensive inspections at every stage, in full compliance with ISO 9001 standards.