The filter cloth, as the core component of filter equipment, has a primary function of liquid-solid separation. The selection of filter cloth not only affects production efficiency, but also energy consumption and the service life of the equipment. The glue coating processing is a crucial link in the production and processing of filter cloth.

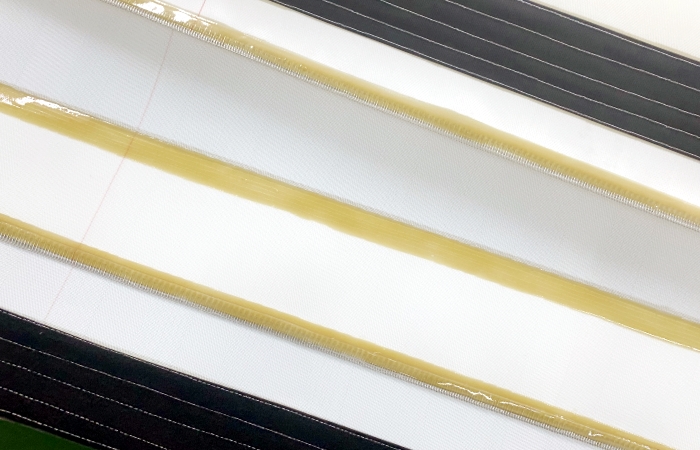

The glue coating is primarily applied to protect the edges or joints of filter cloth. Its function at the joints is to protect the seam clipper or overlap. In high-intensity or high-force equipment operation, it is essential to ensure that seam clipper does not break easily. During the glue coating process, ensuring the adhesive fully penetrates the cloth makes a secure bond.

Applying glue coating to the length edges of filter cloth is an effective method of protecting against fraying. However, the majority of the filter cloth currently does not require edge glue coating. This is because Bolian uses ultrasonic edge-sealing machines, through wave energy for cutting and processing, resulting in a clean cut that is not prone to chipping or sticking to the blade, and does not generate a fusion effect during cutting. Edge sealing of the cutting part prevents the fabric material from fraying.

BOLIAN strictly adheres to the ISO9001 process, meticulously testing each stage of production. This ensures that each product and each piece of filter cloth meets the requisite quality standards.