Tissue forming fabric is a crucial part in the manufacturing process of paper, with its quality and operational efficiency directly impacting the final product's quality. A complex issue arises from the deviation of the forming fabric during running, which can result in a decline in paper quality, abrasion of the forming fabric, as well as folding. Consequently, it is imperative to undertake a thorough analysis of the forces that contribute to the deviation of the forming fabric.

Firstly, from a mechanical standpoint, when the roll shaft of the paper machine is not parallel, the forming fabric will be subjected to uneven lateral pressure during operation, thus generating deviation. Furthermore, the jamming or failure of the equipment guiding device will also render the forming fabric unable to be corrected in time, thus exacerbating this phenomenon.

Tension is a vital factor in determining the stability of the forming fabric during operation. Insufficient or excessive tension can result in the deviation issue. Insufficient tension results in the fabric's position being susceptible to external forces, leading to its displacement within the equipment. Conversely, excessive tension can cause the fabric to undergo overstretching, resulting in deformation and subsequent deviation.

In instances where the pulp flow exhibits non-uniformity, an imbalance in force is generated on the forming fabric, consequently leading to the deviation. This phenomenon is particularly pronounced in high-speed paper machines, where the rapid movement of the pulp leads to a corresponding increase in the impact force on the forming fabric. This, in turn, increases the probability of deviation. In addition to the aforementioned factors, the physical characteristics of the forming fabric itself are also an important factor affecting its stability. In the case of ordinary paper mesh, its poor tensile capacity renders it susceptible to stretching deformation. When the limit of expansion and deformation exceeds the adjustment range of the paper machine, the phenomenon of deviation is likely to occur.

In the operation of the paper machine, it is also necessary to strengthen the maintenance and repair work of the forming fabric. The regular inspection and fastening of equipment components is imperative to ensure the stability and reliability of the equipment. The timely replacement of severely worn forming fabrics is crucial to avoid excessive abrasion and lead to deviation. Furthermore, the strengthening of the cleaning and lubrication of the forming fabric is essential to reduce the friction resistance between it and the pulp, thereby improving operational efficiency.

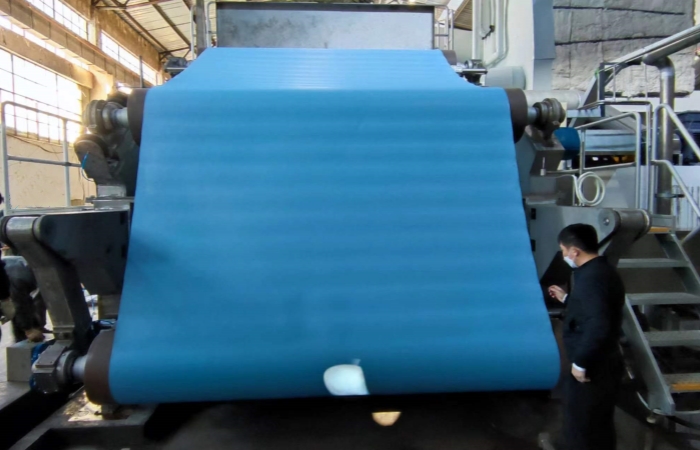

BOLIAN filtration materials adheres to a stringent process during the production of its products. Each stage of the production process is subjected to rigorous and meticulous testing in accordance with ISO9001, thereby ensuring that each batch of products and each piece of filter cloth meets the requisite quality testing standards.