The filter cloth, which serves as the primary component of the filter, is applied in the liquid-solid separation, where it plays a crucial role when the filter is in operation. The main materials include polypropylene, polyester, polyamide, non-woven fabric, and other materials.

Tower press filter cloth in the modified starch industry

In the marketplace, tower press filters are used to filtrate modified starches with a particle size of 5-10μm. The technical challenge in this industry is to filter ultra-fine particles. One common issue is excessive air permeability, thus, ultra-low air permeability filter cloth is the key solution to this problem.

Bolian technical team engaged in comprehensive customer communication to gain a deep understanding of the challenges they were facing. After years of research and testings, we successfully designed an ultra-fine vertical filter cloth. This product is featured with the filtration accuracy of 5-10μm, while maintaining the original anti-stretching performance and service life. It has been successfully implemented in the modified starch industry to assist customers in addressing the challenge of ultra-fine particle filtration.

Horizontal vacuum belt filter cloth used in the lithium industry

The growth in demand for lithium materials driven by the development of electric vehicles has led to the need for more efficient lithium ore extraction technology, making the lithium ore into a lithium resource of industrial significance. The product is a kind of belt cloth designed for extracting lithium carbonate from the lithium ore. It is processed with the same method of high-strength, low-elongation, The product is a kind of belt cloth designed for the extraction of lithium carbonate from lithium ore. It is processed with the same method of high-strength, low-elongation filter cloth, enhancing its durability.

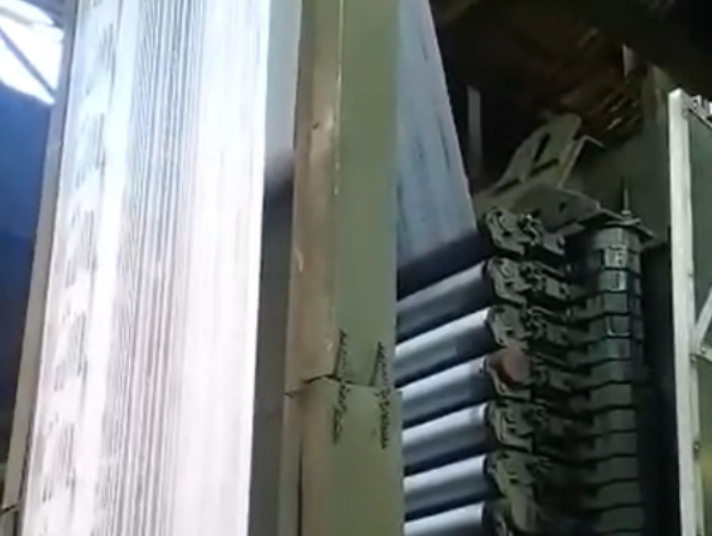

Diaphragm cloth used in the electrolysis and electrowinning

Bolian electrolytic diaphragm cloth products offer advantages in stable water permeability, internal and external liquid retention, low energy consumption, and durability. We possess one invention patent and two utility model patents. Furthermore, we actively promote and participate in the formulation of evaluation standards for electrolytic diaphragm products, which provides a solid foundation for the development of the industry.

Filter press cloth in the food industry

Our filter press cloths are widely recognized by customers in the food industry for their durability, clogging resistance, long service life, and high filtration accuracy, and have passed the FDA and EU No. 10/2011 European Union food-grade certifications, ensuring safety for use with food products.