Yarns

Yarns are the fundamental elements of the woven filter fabric. In traditional textile manufacturing, it has been common first to make yarn from fibers, and then produce a fabric from the yarn. Generally, yarn is defined as a linear assemblage of fibers or filaments formed into a continuous strand.

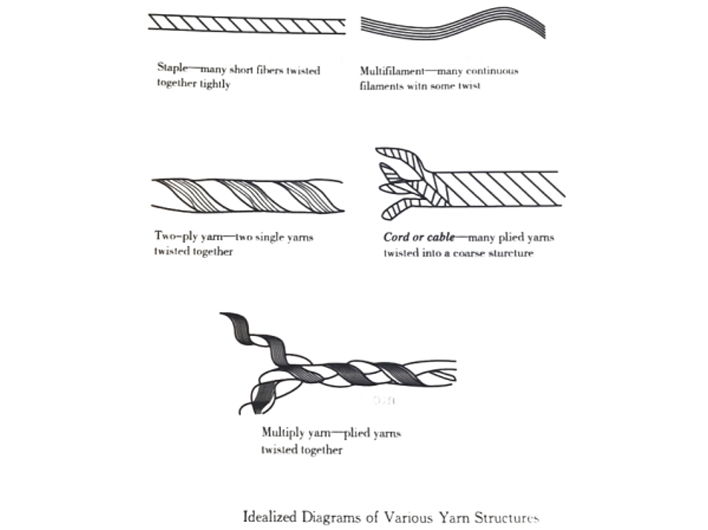

Yarns may be composed of one or more continuous filaments or of many non-continuous and rather short fibers(staple). To overcome fiber slippage and to form into a functional yarn, staple fibers are usually given a great amount of twist or entanglement. Yarns made from staple fibers are often referred to as spun yarns. Two or more single yarns can be twisted together to form ply or plied yarns.

There are two methods of making the yarns. With one method, the yarn is produced from staple fibers and called staple yarn; with the other method, the yarn is made from filament fibers and identified as filament yarn or thrown yarn.

Staple yarns, or spun yarns, are made from the staple fibers which include natural fibers such as cotton, wool or linen , and man-made fibers such as polyester, polyamide or acrylic. Yarns made from mixtures of natural and man-made fibers are referred to as “blended" yarns. The filter cloth woven with short fiber yarns is effective at trapping fine particles, but they have limited reusability.

Filament yarns

Filaments are classified into two kinds: natural filament such as silk and man-made filaments such as polyester and viscose. Filament yarns consisting of only a single filament are called monofilaments and those consisting of two or more single filaments are called multifilaments. The surface of monofilament fabric is smooth, and the fabric has high air permeability, which is suitable for intercepting particles but not for trapping fine particles. The fabric has high strength, low elongation, good dimensional stability, and is not easy to fold. The multifilament fabric has good filtration residue stripping and high strength. It is more suitable for trapping fine particles and has better filtration accuracy.

Yarn quality is crucial in the production of filter cloth and can be evaluated from many aspects.

Yarn linear density

The linear density of a yarn is the specification that corresponds to yarn thickness, There are two major systems used to calculate it: one is the weight based (fixed length) system, and the other is the length based (fixed weight)system.

Yarn twist

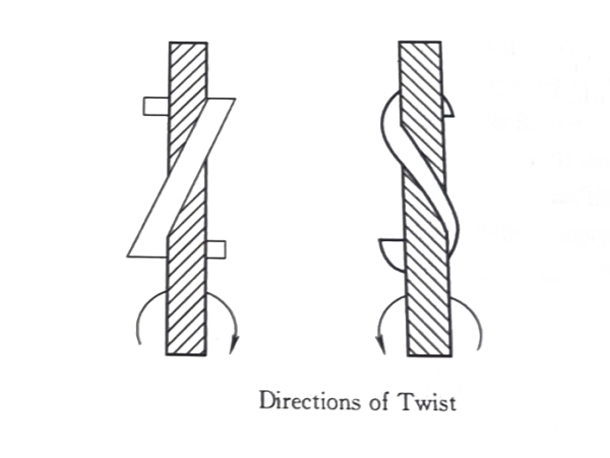

Yarn twist is defined as the number of turns or twists per unit length of a yarn. The more turns per unit length has, the greater cohesive forces between the fibers will be, up to a critical point. Twists can be made as left handed (S) direction, or right handed (Z) direction.

Yarn strength and elongation

Yarn strength, especially the tensile strength and associated breaking elongation, are the important mechanical parameters that need to be controlled.

Therefore, it is important to consider various types of yarns when selecting industrial filter cloth, based on the particle size, the filtration accuracy, and the durability of the filter cloth.