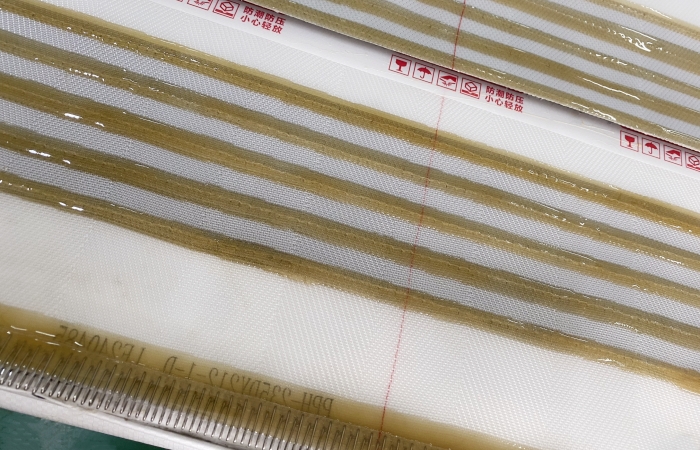

Polyester filter cloth, recognized as a leader in the industrial filtration sector, plays an indispensable role across various industries such as chemicals, metallurgy, pharmaceuticals, and environmental protection due to its unique performance advantages.

Material Characteristics: High Strength, Good Wear Resistance

Polyester, formally known as polyethylene terephthalate (PET), is characterized by high strength, excellent wear resistance, and remarkable high-temperature stability. The molecular structure of polyester fibers is tightly and orderly arranged, endowing the filter cloth with exceptional tear strength and tensile strength that ensure reliability for long-term use.

Physical Performance: Good Air Permeability, High Filtration Precision

Polyester filter cloth boasts outstanding air permeability, which effectively reduces resistance during the filtration process while enhancing overall filtration efficiency. Furthermore, its fibers exhibit uniform fineness and a well-distributed pore size range that allows for precise control over filtration accuracy. The consistent fineness of the fibers combined with appropriate pore distribution facilitates meticulous regulation of filtration precision.

Chemical Stability: Corrosion and Aging Resistance

Polyester filter cloth demonstrates remarkable chemical stability by maintaining consistent performance across a broad pH range (3-9), rendering it resistant to corrosion and degradation. Additionally, polyester fibers possess excellent anti-aging properties.

Application Examples: Widely Used in Multiple Fields

Polyester filter cloth is compatible with various filtration equipment, including horizontal vacuum press filters, Tower press filters , press filters, leaf filters, drum filters, and disc filters. Owing to its superior characteristics, polyester filter cloth has found widespread application in numerous industrial sectors including chemical processing, metallurgy, pharmaceuticals, and environmental management.