Hydrogen is one of the most abundant elements in the Earth's crust and possesses notable characteristics, including a high calorific value, zero emission and renewability. In a combustion or fuel cell reaction, hydrogen combines with oxygen to form water while releasing a substantial amount of energy. The sole by-product of this process is water, thus hydrogen energy is regarded as an optimal clean energy source.

As the hydrogen energy industry continues to evolve, so too does the technology used to produce hydrogen. On the one hand, traditional hydrogen production technologies, including natural gas hydrogen production and coal gasification hydrogen production, are undergoing continuous improvement. On the other hand, emerging hydrogen production technologies, such as water electrolysis hydrogen production and biomass hydrogen production, are also being developed. In the future, the development of hydrogen production technology will be oriented towards the protection of the environment, high efficiency and economy.

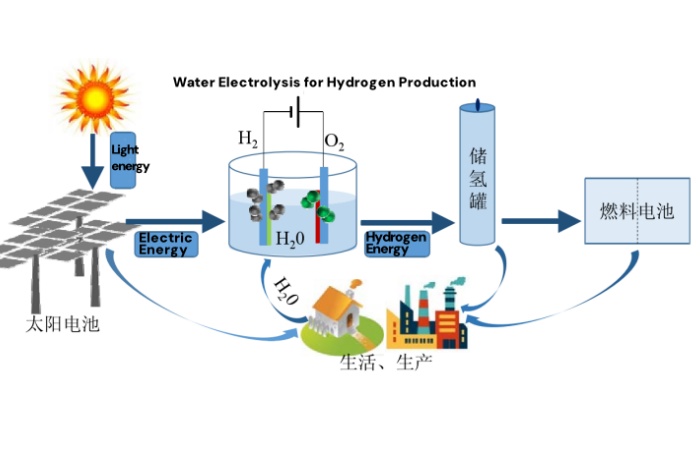

Hydrogen production by water electrolysis represents a more environmentally friendly approach to hydrogen generation, which is based on the principle that water is broken down into hydrogen and oxygen by electrolyzing water. In the electrolysis process, the requisite apparatus includes an electrolyzer, electrodes, a diaphragm, and other ancillary equipment. The advantage of hydrogen production by water electrolysis is that it is environmentally friendly and non-polluting. Furthermore, the hydrogen produced can be used as a fuel or chemical raw material, while the oxygen generated can be employed for oxygen-enriched combustion or production. The disadvantage of hydrogen production by water electrolysis is the high energy consumption and the necessity for a substantial amount of power support. In light of the accelerated growth of renewable energy sources, hydrogen production by water electrolysis has emerged as the sector with the most promising market potential for zero-carbon hydrogen generation. Currently, ALK (Alkaline Electrolyzer) hydrogen production technology is well-established and widely applied. In contrast, PEMD (Proton Exchange Membrane) hydrogen production is a relatively recent development, yet its cost remains prohibitively high. Meanwhile, the third generation of electrolytic water hydrogen production technology, AEM (Anion Exchange Membrane), is still in its infancy and requires further technological breakthroughs to reach the same level of maturity as ALK and PEM technology.

In order to satisfy the requirements of electrolytic hydrogen production, it is essential that the electrolytic hydrogen diaphragms materials are characterized by a low thickness and high porosity. The diaphragm should also exhibit high air tightness and structural stability during the production process.